| Items |

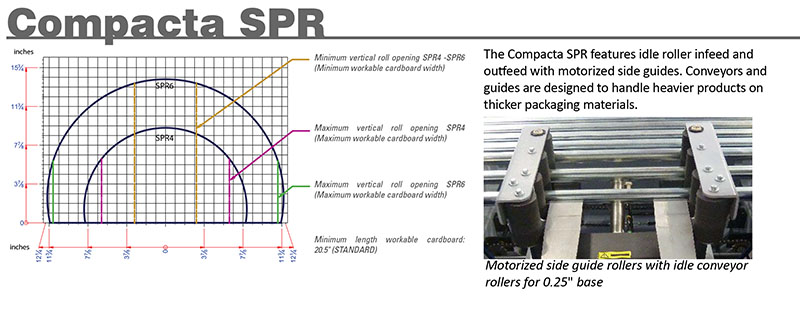

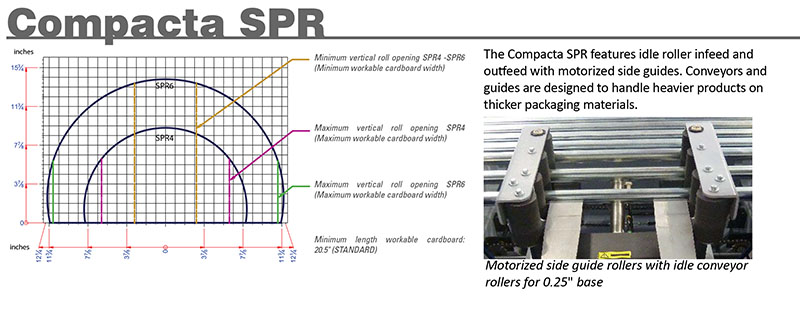

/Asset/a2143.jpg /Asset/a2143.jpg 3778 Compacta SPR4, 31.6 Inch (in) Infeed/Outfeed Table Height Semi-Automatic Horizontal Stretch Bundling Wrapping Machine |

/Asset/a2143.jpg /Asset/a2143.jpg 3779 Compacta SPR6, 34.4 Inch (in) Infeed/Outfeed Table Height Semi-Automatic Horizontal Stretch Bundling Wrapping Machine |

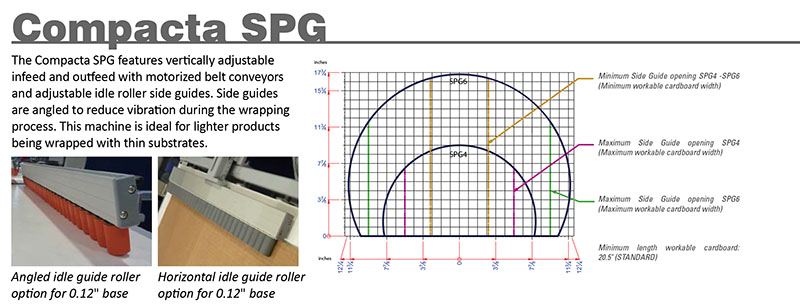

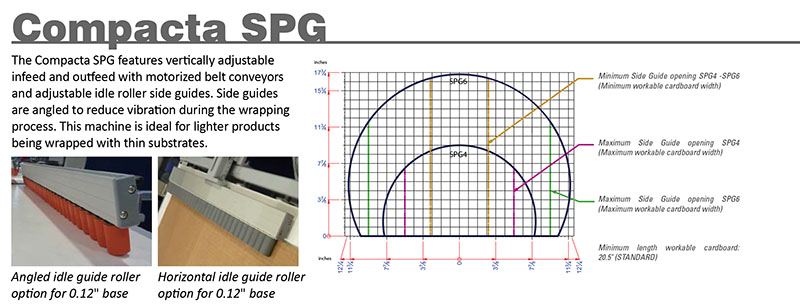

/Asset/a2142.jpg /Asset/a2142.jpg 3780 Compacta SPG4, 31.5 Inch (in) Infeed/Outfeed Table Height Semi-Automatic Horizontal Stretch Bundling Wrapping Machine |

/Asset/a2142.jpg /Asset/a2142.jpg 3781 Compacta SPG6, 31.5 to 36.2 Inch (in) Infeed/Outfeed Table Height Semi-Automatic Horizontal Stretch Bundling Wrapping Machine |

||||

| Description | N/A The Compacta SPR features idle roller infeed and outfeed with motorized side guides. Conveyors and guides are designed to handle heavier products on thicker packaging materials. | N/A The Compacta SPR features idle roller infeed and outfeed with motorized side guides. Conveyors and guides are designed to handle heavier products on thicker packaging materials. | N/A The Compacta SPG features vertically adjustable infeed and outfeed with motorized belt conveyors and adjustable idle roller side guides. Side guides are angled to reduce vibration during the wrapping process. This machine is ideal for lighter products being wrapped with thin substrates. | N/A The Compacta SPG features vertically adjustable infeed and outfeed with motorized belt conveyors and adjustable idle roller side guides. Side guides are angled to reduce vibration during the wrapping process. This machine is ideal for lighter products being wrapped with thin substrates. | ||||

| Brands | N/A Robopac® | |||||||

| Maximum Rotation Speed | N/A 160 rpm | N/A 120 rpm | N/A 160 rpm | N/A 120 rpm | ||||

| Wrapping Cycle | N/A Banding Continuous | |||||||

| Manual Top Pressure Unit Infeed and Outfeed | N/A Optional | |||||||

| Power Supply Voltage | N/A 110 V | |||||||

| Phase | N/A 1 | |||||||

| Installed Power | N/A 1 hp | |||||||

| Working Pressure | N/A 90 psi | |||||||

| Film Width | N/A 5 in | |||||||

| Maximum External Diameter | N/A 8 in | |||||||

| Core Diameter | N/A 3 in | |||||||

| Length | N/A 70.5 in | N/A 71 in | N/A 90.2 in | N/A 90.2 in | ||||

| Width | N/A 49.5 in | N/A 57.6 in | N/A 49.5 in | N/A 57.6 in | ||||

| Height | N/A 53 in | N/A 60.8 in | N/A 53 in | N/A 60.8 in | ||||

| Infeed/Outfeed Table Height | N/A 31.6 in | N/A 34.4 in | N/A 31.5 in | N/A 31.5 to 36.2 in | ||||

| Infeed/Outfeed Table Width | N/A 17.87 in | N/A 32.2 in | N/A 12 in | N/A 19.7 in | ||||

| Industry Standards | N/A European Conformity (CE) | |||||||

| Specifications |

N/A

Compacta SPR |

N/A

Compacta SPR |

N/A

Compacta SPG |

N/A

Compacta SPG |

||||

| Suspended Packaging |

N/A

Suspended packaging allows you to eliminate packaging materials necessary to protect fragile products. By wrapping the product to a substrate, the product is protected from the outer packaging; vibration is reduced and the outer packaging is reinforced by the insert. It secures multiple pieces to the substrate. Assembly parts are easily combined on a single flat surface. No more lost parts in the bottom of the box. Suspended packaging eliminates the need for additional packaging components to protect your product like peanuts, bubble wrap, styrofoam forms, air pillows and foam pillows-saving you money in packaging materials and freeing up space in y our warehouse. It also makes inserting and removing the product easier and faster. Both models can be adjusted to accommodate different thicknesses of cardboard, but the Compact a SPR is better suited for extremely thick cardboard. Wrap settings can be adjusted to match containment force with the rigidity of the base material. Standard 5-inch roll carriage allows you to select from a wide variety of films to best suit your load. |

|||||||

| Features |

N/A

|

N/A

|

N/A

|

N/A

|

||||

| Additional Information |

N/A

Units are available with a variety of product stabilization and sealing devices. This versatility allows our Compacta machines to quickly and easily adapt to different product types, shapes and sizes and makes them the ideal solution f or almost any application. Robopac® leads the industry with innovative products and solutions. The new Compacta machines prove that we are committed to providing you with the best machinery combined with the latest technology. Our engineers wouldn't allow us to do it any other way. Larger items with sensitive pieces like electronic components, optics, calibrated parts benefit from suspended packaging. Fragile products including electrical components, PCBs, pneumatic kits and gearboxes are also excellent candidates for wrapping on the Compacta SPR. Multiple items can be wrapped to the base, reducing lost items and speeding up assembly time. Products can be easily inserted and removed. |

|||||||

|

|

||||||||